Oil Filtration Products

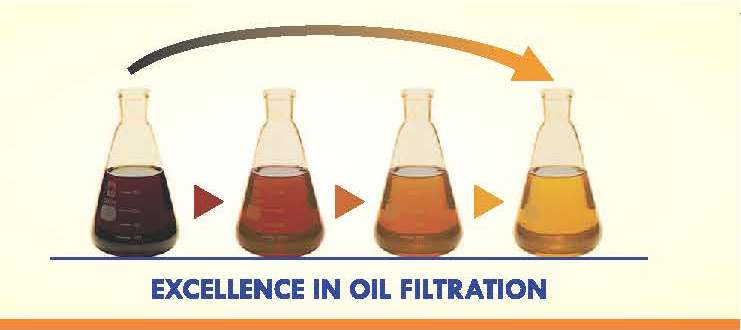

Offering Solutions for Sustainable Oil Management with State of Art Technology from RRR Japan (Oil Filters & Oil Cleaners)

Facts

1. Machine manufacturers, always “Suggest” an Oil change interval based on a predicted level of contamination within machine Oil.

2. Any equipment using oil for power transmission, lubrication or combustion will be affected by the condition of the oil.

3. Solid particles and Moisture account for the majority of all failures in an lubrication system.

4. The best way to control the contamination in any lubrication process is to stop the contaminants from entering the system.

Why contamination needs to be controlled?

50% reduction in bearing purchases plant-wide

80% reduction in hydraulic pump replacement

Optimise oil consumption

90% reduction in pump overhauls

90% reduction in frequency of lubrication failures

How Mridi Logic does it!

Removing maximum solid particle contaminants ( maintain desired NAS/ISO levels )

Maintaining the Rate of contamination Removal Greater than Rate of Generation (R>G)

Maintaining the moisture content under acceptable limits by absorption.

All with a single system for all viscosity grades ISOVG 22- 680

Where it can be used: All Cement Companies, Power Generating Companies, Steel Manufacturing Companies, Automobile Manufacturing Companies etc were different types of oils are used like Turbine Oils , Gear Oils, Hydraulics Oil,Engine oil

Product:BU Series, SE Series, OSCA Series